Heat Transfer Oil

Heat Transfer Oil (Thermal Oil)

What is Heat Transfer Oil?

Heat transfer oil refers to a special fluid (often called heat transfer fluid or thermal oil) that is used as a medium for heat transfer from a heat source to cooler conducting materials. Heat transfer is a complex process involving several steps, which are temperature dependent and finitely controlled. It is widely used in the food and chemical processing industries, in the automotive and lighting industry, as well as in the manufacturing, construction, mining and power generation industries.

Heat transfer is usually performed through radiation, convection, or convective heating, all of which are performed in an environment which is strictly managed. The heat transfer fluid’s temperature is often controlled, and the fluid’s rate of diffusion is also altered to provide the best results. Heat conduction is typically divided into two categories: direct and indirect.

Direct Heat Transfer vs. Indirect Heat Transfer

Direct Heat Transfer

Direct heat transfer is the most energy efficient way to transfer heat from one location to another. The most common example of a direct heat transfer oil would be water heated in a boiler to the appropriate temperature and then transferred to a process under 100°C or made into steam if the process needs temperatures above boiling point.

However, boilers are pressure vessels and are therefore strictly managed to maintain safety to people and property.

Indirect Heat Transfer

Indirect heat transfer involves transferring heat from one location to another, usually in the form of a heat transfer oil that travels between two locations through conductive means (i.e. a physical barrier such as a wall or a space filled with air). This means that the thermal oil can have a temperature above 100°C but maintain its liquid form and therefore get around the need for a pressure vessel (such as a boiler).

Uses & Applications

Heat transfer is used in a wide variety of different industries, including: solar panel manufacturing, thermal oxidizer plants, dry cleaning, chemical processing, gold mining and the drying of wood.

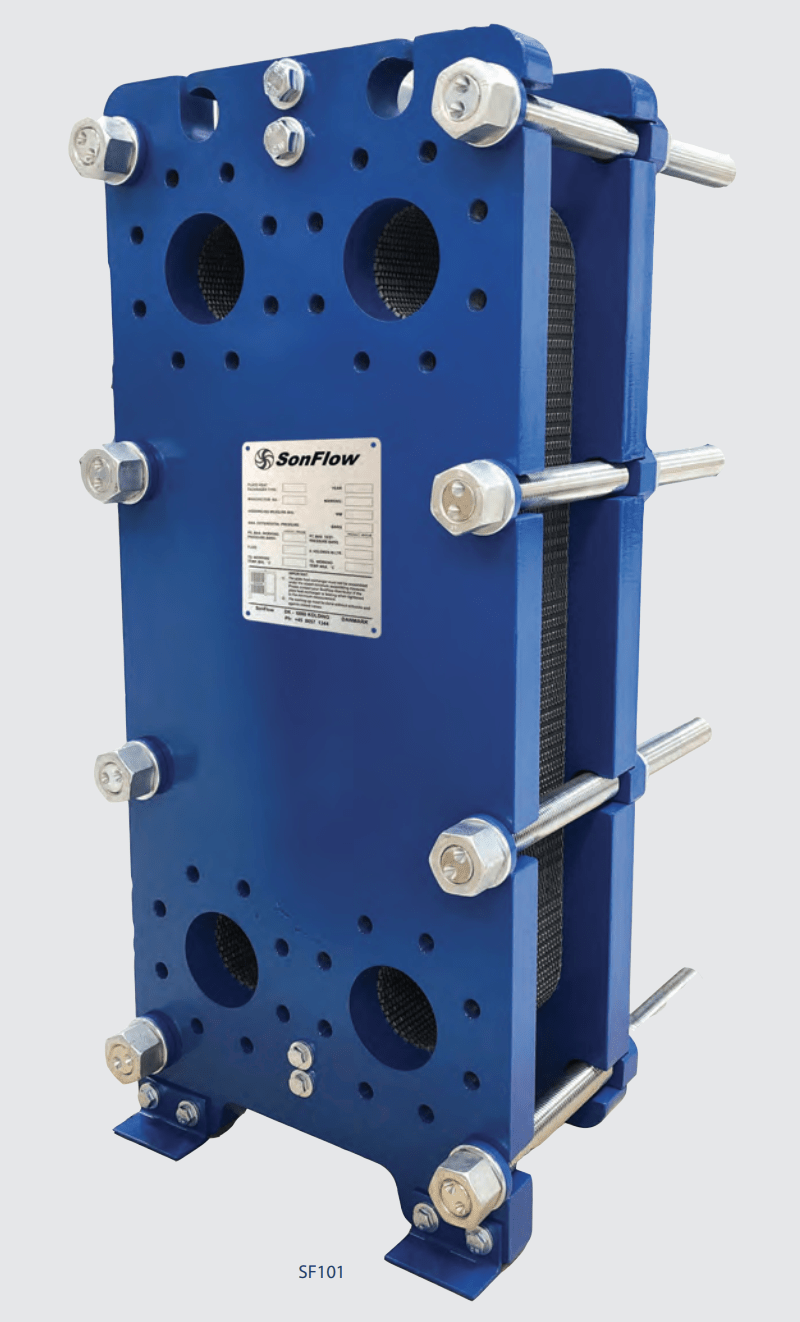

Some applications transfer the heat from the thermal oil to a cooler medium through the use of heat exchangers. These items usually come in the form of shell and tube heat exchangers or plate and frame heat exchanges. These units work by having the hot fluid flowing through the exchanger on one side of a physical barrier (generally a metal tube or metal plate wall) where the heat is picked up by the barrier and transferred via heat conduction into the cooler fluid on the other side.

Because some of these processes involve the transfer of heat at different temperature levels, some types of heat transfer fluid must have a specific temperature and a higher flash point in order to work. This means that different variants of thermal oil would be better at specific tasks than others. An excellent example would be the Duratherm S, which has the industry’s highest flash point of 324°C and can be used for processes requiring incredibly high temperature transfer.

LEARN MORE: Why thermal oil is necessary in the elution circuit

Heat Systems is the Australian Distributor for the Duratherm range of thermal oil products and cleaners.

The Duratherm line of thermal oils has expanded to include heat transfer fluids capable of operating temperature ranging from -85°C to 337°C. As an agent of Duratherm we can offer industry leading, 24/7 technical support, comprehensive engineering data, free heat transfer oil analysis and fast order processing and expedited shipping to keep your downtime to a minimum.

Cleaner running, longer lasting thermal oil

Most heat transfer fluids transfer heat and cool with a reasonable degree of efficiency. What really makes the difference though is how long a heat transfer oil lasts and how clean it keeps your system. Backed by decades of research and hands-on experience, Duratherm’s development team continues to work hard to advance our industry-leading, thermal oil technologies.

The Difference

We have selected Duratherm as they are a global leader in the thermal oil industry with a reputation built on providing outstanding customer service and technical support. Our dedicated team of professionals have extensive experience working with both end-users and our OE partners. We’re always available to help you meet your needs across a wide variety of applications.

- Comprehensive engineering and technical support

- Complete engineering data available for our full line of thermal oils

- Lifetime complimentary in-house heat transfer oil analysis

- Custom thermal oils engineered to your exact needs

- OEM product development assistance and private label

Just about any fluid will transfer heat with some degree of efficiency; it’s how long it lasts and how clean it keeps your system while it’s running that makes the difference.

Duratherm’s range of various highly stable, naturally resilient, base heat transfer fluids continues with a proprietary blend of additives. These aren’t just off-the-shelf generic additives; their package is finely tuned and formulated specifically for high temperature thermal oil use and the most demanding of applications.

While some might say the use of additives is not necessary, click on the link below and decide for yourself if your system needs the extra protection of Duratherm.

Collection of thermal oil samples are not collected in a representative method, artificially high flash point values will be returned. This results in the end user perceiving a lower risk from flash points than is actually correct.

This has obvious insurance, health and safety and, with the effect of the new (EUROPE) regulations, important legislative implications.

The Legal Requirements for Thermal Fluid Systems and Representative Fluid Analysis DSEAR (Dangerous Substances & Explosive Atmospheres Regulations 2002).

Health and safety legislation, requiring that employers provide a safe working environment, has been around for a long time. In the past, just how that was to be achieved was largely up to the employer.

Now, where flammable materials that could create an explosive atmosphere are being handled, DSEAR (ATEX/CAD in Europe) set out a mechanism for minimising the risks. Employers have a legal obligation not only to abide by this but to

prepare and maintain documentary evidence.

Oxidative Degradation (Most Common)

Oxidation occurs when heated fluid is exposed to air. It is one of the most common forms of degradation and can lead to the formation of sludge. While various heat transfer oil chemistries oxidize at different temperatures, Duratherm thermal oils will normally start to oxidize above 93°C. It is also generally accepted that for every 15C° increase in temperature above 93°C, the rate of oxidation doubles.

Heat Systems Products

Heat Systems Carbon Regeneration Kilns are ideal for all Carbon Reactivation & Recovery needs and designed with three factors in mind.

Carbon Regeneration Kilns

Heat Systems offer gold furnaces in a range of sizes designed for efficient, high-temperature use with minimal maintenance.

Smelting Furnaces

Heat Systems offer an extensive range of quality heat transfer oils that are cleaner running, longer lasting thermal fluids.

Heat Transfer Oils

Heat Systems designs and manufactures complete thermal oil elution heaters or direct eluate heating packages to suit your process requirements.

Elution Heaters

The Heat Systems screw conveyors are simple, robust and flexible, and are often employed to adjust the temperature of a solid material prior to storage or further processing.

Screw Conveyors

HEAT Systems don’t just supply you with off the shelf items, we manufacture them with you in mind. This gives us an intrinsic knowledge of the thermal heaters and equipment we supply.