Elution Heaters

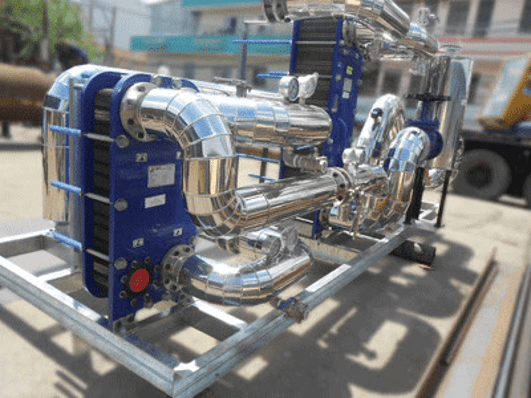

Whether you are looking for a Zadra or split Anglo (AARL) elution heater for your mine site, Heat Systems has the complete eluate heating equipment package for your needs. Our elution heaters can come as either a direct eluate heater, or as a thermal oil heater (where the heat is transferred from the oil to the eluate via a suitably sized heat exchanger). Both versions can be sized specifically to suit your exacting requirements.

A direct eluate heating solution within a Zadra circuit is the most cost effective and less complex of the elution heating solutions. The direct heating of the eluate allows for poor site water quality, ease of management and less components that need to be maintained and replaced.

The indirect elution heating solution requires more infrastructure than the direct eluate heating option, such as multiple heat exchanges, piping and control points. Additionally, this style of heating requires a heat transfer fluid to absorb the heat and then transfer that heat into the eluate through the primary heat exchanger. Although this is a more complex solution, it is widely used due to the ability to manage the circuit more finitely.

Heat Systems standard thermal oil heaters and direct eluate heaters are LPG, Natural Gas, Diesel or electrically fired, while custom designed heat plants are available on request for clients looking to utilise waste heat, solid fuel or heavy fuel oil.

Control system options are available to suit the needs and budget of any project. Starting with basic relay logic panels and progressing through to programmable logic controllers with touch screens and the latest technology air/fuel ratio burner management systems.

Whether the unit required is indirect elution heater or direct eluate heater, all units come skid mounted for ease of transport and installation.

Heat Systems is the Australian Distributor for the Duratherm range of thermal oil products and cleaners.

- Size 300 – 10,000 kW

- Pressure 2 – 20 bar g

- Temperature 80 – 150° C

- Natural Gas, LPG, Diesel, Duel Fuel

- Full stainless steel wetted parts

- High flow-rate to ensure low water side fouling

- High efficiency, up to 87%

- Long-life insulation with stainless steel cladding

- Thermal oil, Glycol or Steam as heat transfer medium

- Primary & Recovery plate heat exchangers

- Skid mounted

- High efficiency, up to 87%

- Ideal for poor water quality plants

Heat Systems Products

Heat Systems Carbon Regeneration Kilns are ideal for all Carbon Reactivation & Recovery needs and designed with three factors in mind.

Carbon Regeneration Kilns

Heat Systems offer gold furnaces in a range of sizes designed for efficient, high-temperature use with minimal maintenance.

Smelting Furnaces

Heat Systems offer an extensive range of quality heat transfer oils that are cleaner running, longer lasting thermal fluids.

Heat Transfer Oils

Heat Systems designs and manufactures complete thermal oil elution heaters or direct eluate heating packages to suit your process requirements.

Elution Heaters

The Heat Systems screw conveyors are simple, robust and flexible, and are often employed to adjust the temperature of a solid material prior to storage or further processing.

Screw Conveyors

HEAT Systems don’t just supply you with off the shelf items, we manufacture them with you in mind. This gives us an intrinsic knowledge of the thermal heaters and equipment we supply.